Assessing the friction performance of powder metallurgy materials requires precise evaluation methods, one of which is measuring the sample's weight loss to determine wear resistance. This approach offers valuable insights into the durability of various coatings. Additionally, lubrication plays a crucial role in these assessments. By using different lubrication conditions, such as dry friction or oil lubrication, our testing simulates real-world scenarios, allowing for more accurate evaluations of wear resistance. The friction speed is another important factor; different speeds can trigger varying wear mechanisms in powder metallurgy materials. Adjusting the speed helps to evaluate the material’s durability under different working conditions. Our various models of testing machines adhere to GB/ISO/ASTM standards and uses comparative testing to ensure the reliability of test methods and results.

Classification of Firction Pairs by Relative Motion

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing Block-on-ring friction testing

Block-on-ring friction testing Reciprocating friction testing

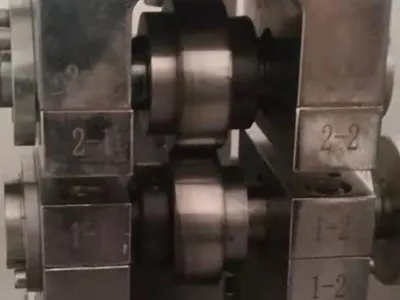

Reciprocating friction testing Rolling fatigue friction testing

Rolling fatigue friction testing

Classification of Firction Pairs by Environmental Medium

- Dry friction testing

- Lubricated friction testing

- Friction testing under various environmental conditions (High and Low Temperature, high humidity, vacuum, salt spray, current carrying, electrochemical)

- Friction testing under other special conditions