Chemical materials are integral to countless industrial applications, where their durability and performance can significantly impact product quality and longevity. Friction and wear testing provides critical insights into how these materials respond to different conditions, allowing industries to evaluate key factors like friction coefficient and wear rate. With this information, manufacturers can make informed decisions on material selection and application. Our testing equipment meets ASTM G65 standards, offering a reliable solution for a variety of testing scenarios to support the development and application of high-performance chemical materials.

Classification of Firction Pairs by Relative Motion

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing Block-on-ring friction testing

Block-on-ring friction testing Reciprocating friction testing

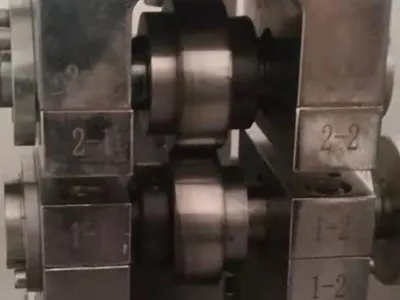

Reciprocating friction testing Rolling fatigue friction testing

Rolling fatigue friction testing

Classification of Firction Pairs by Environmental Medium

- Dry friction testing

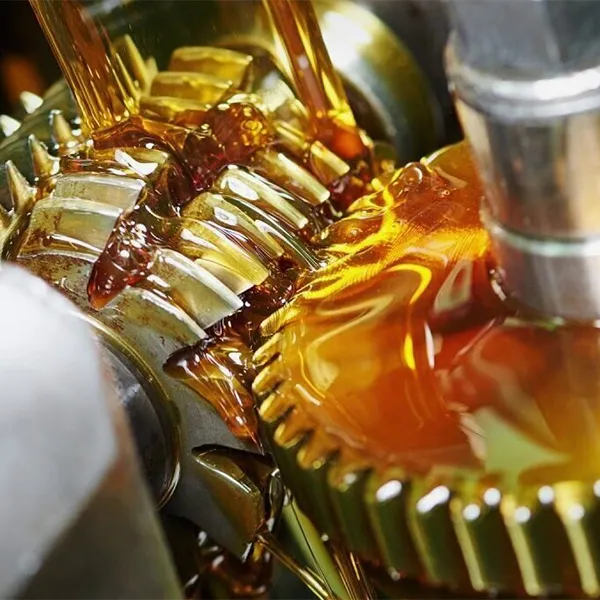

- Lubricated friction testing

- Friction testing under various environmental conditions (High and Low Temperature, high humidity, vacuum, salt spray, current carrying, electrochemical)

- Friction testing under other special conditions