Tungsten carbide, known for its high hardness and superior wear resistance, requires precise friction testing to evaluate its performance in real-world applications. These tests help identify potential wear patterns that tungsten carbide may encounter in industrial use, allowing for optimized design and application to enhance the performance and lifespan of mechanical components. As the industrial sector continues to evolve, the demand for understanding the tribological properties and stability of tungsten carbide under specific environmental conditions has increased significantly. This is not only important in traditional industries but is also gaining attention in fields like biomedicine and decorative surfaces. Our equipment complies with standards such as ASTM G65 and ASTM-B611-85, providing reliable and high-quality friction testing solutions.

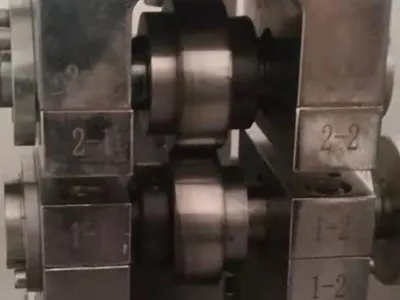

Classification of Firction Pairs by Relative Motion

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing Block-on-ring friction testing

Block-on-ring friction testing Reciprocating friction testing

Reciprocating friction testing Rolling fatigue friction testing

Rolling fatigue friction testing

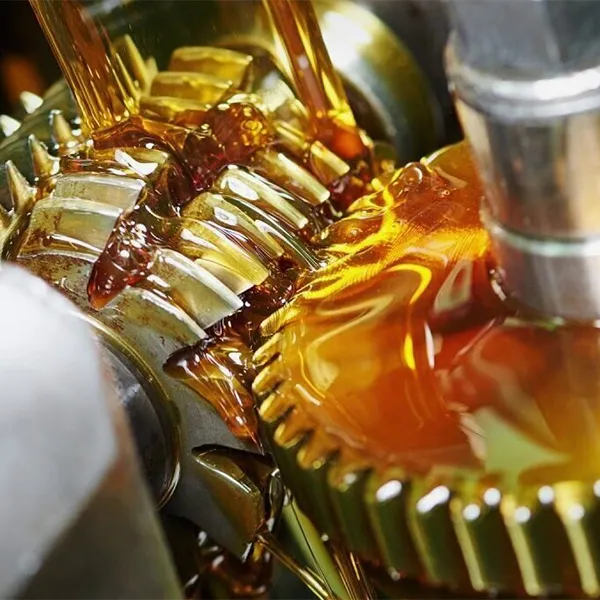

Classification of Firction Pairs by Environmental Medium

- Dry friction testing

- Lubricated friction testing

- Friction testing under various environmental conditions (High and Low Temperature, high humidity, vacuum, salt spray, current carrying, electrochemical)

- Friction testing under other special conditions