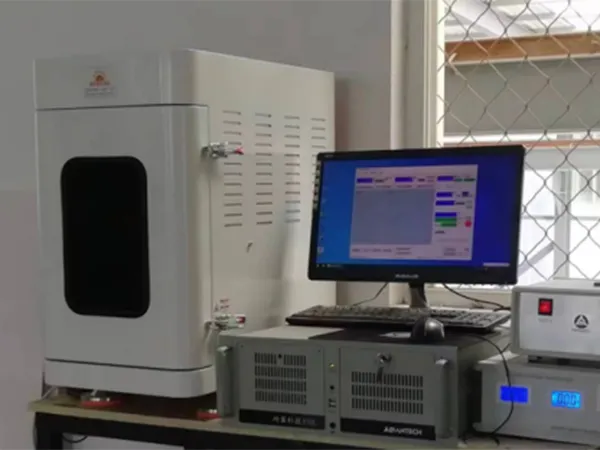

A friction and wear testing machine is an experimental instrument used to study the frictional properties and wear behavior of materials during contact and motion. It is widely applied in mechanical engineering, materials science, and lubrication research.

By setting specific friction conditions such as load, speed, temperature, and environment, the tester simulates real-world operating scenarios to measure key parameters including the coefficient of friction, wear rate, wear resistance, and lubrication performance of materials under various conditions.

These results provide essential data for material optimization, component improvement, and the development of high-efficiency lubrication technologies.

How is the coefficient of friction (COF) measured?

The coefficient of friction (COF) is a parameter used to evaluate how two surfaces interact when they come into contact and move against each other. It applies to a wide range of materials, including lubricants, various metallic and non-metallic materials. The test helps determine how much resistance occurs when one material slides over another, which is essential for optimizing performance and safety in various industries, from manufacturing to consumer goods.