When testing composite materials for friction and wear, the main focus is on evaluating the material's friction coefficient and wear rate. These measurements are critical for assessing the durability and service life of composites in real-world applications, providing essential data for material design and optimization. Additionally, friction testing allows researchers to better understand the wear mechanisms, leading to performance improvements. Our composite material testing equipment meets ASTM G65 standards and ensures high-precision data for your needs.

Classification of Firction Pairs by Relative Motion

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing

Pin-on-disk, ball-on-disk, thrust washer rotary friction testing Block-on-ring friction testing

Block-on-ring friction testing Reciprocating friction testing

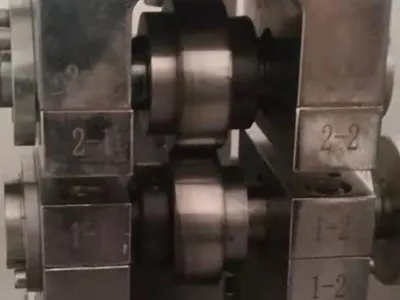

Reciprocating friction testing Rolling fatigue friction testing

Rolling fatigue friction testing

Classification of Firction Pairs by Environmental Medium

- Dry friction testing

- Lubricated friction testing

- Friction testing under various environmental conditions (High and Low Temperature, high humidity, vacuum, salt spray, current carrying, electrochemical)

- Friction testing under other special conditions