-

- Mechanical Testing Machine for Metal Testing When conducting mechanical performance tests on metals, selecting the appropriate testing machine is essential to ensure accurate and reliable results. Click For More Info

-

- Mechanical Testing Machine for Textile Testing Mechanical testing of textiles provides important data that serve as essential references for evaluating fabric quality. Click For More Info

-

- Mechanical Testing Machine for Plastic Testing Given the widespread use of plastics across various industries, it's essential to assess their mechanical properties before application. Click For More Info

-

- Mechanical Testing Machine for Composites Testing When testing the mechanical properties of composite materials, it’s important to evaluate main parameters such as tensile strength, bending strength, shear strength, and impact resistance. Click For More Info

-

- Mechanical Testing Machine for Rubber Testing Mechanical testing of rubber materials requires careful consideration of load capacity, testing type, and the appropriate fixtures to ensure precise results. Click For More Info

-

- Mechanical Testing Machine for Concrete Testing The compressive strength of concrete is a factor in assessing its quality, as it directly affects the safety and longevity of structures. Click For More Info

-

- Mechanical Testing Machine for Fiberglass Testing Fiberglass is a high-performance composite material, typically made from glass fibers and resin, known for its strength and versatility. Click For More Info

-

- Mechanical Testing Machine for Artificial Board Testing Artificial boards, composed of wood fibers or other fiber materials combined with resin or adhesives, are widely used in construction and furniture manufacturing. Click For More Info

Explore More Materials Testing Applications

-

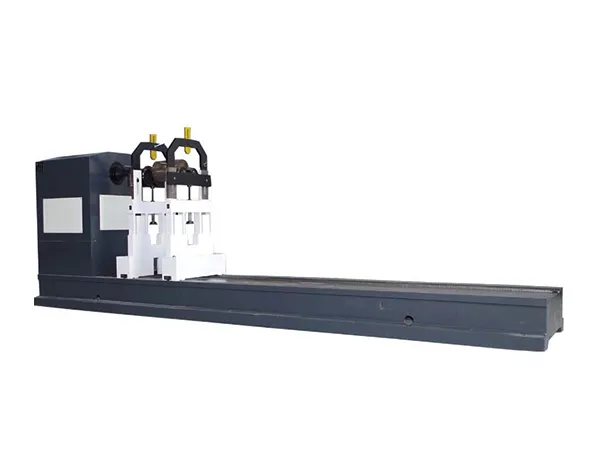

- Friction & Wear Testing Friction and wear testing is critical for evaluating the performance and durability of materials in industries like automotive, aerospace, and manufacturing. Click For More Info

-

- Dynamic Balancing We offer tailored dynamic balancing solutions based on the type of rotating parts, while considering factors such as weight, diameter, thickness, and the dimensions of the connecting components. Click For More Info