-

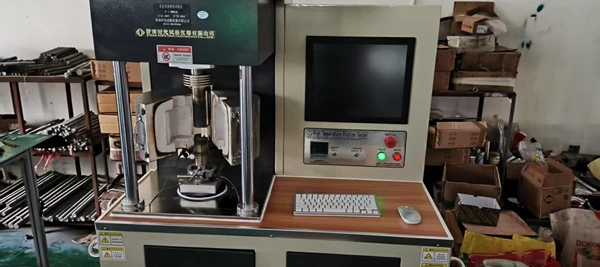

In August 2025, a university research team in Beijing used the MPX-3X pin friction and wear testing machine to study the wear resistance of nickel-based alloy materials and coating surfaces, obtaining satisfactory testing results.

-

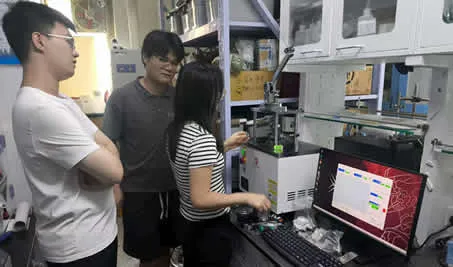

In February 2023, the Nickel Alloy Research Laboratory utilized the pin ball on disc testing machine to study the wear resistance of nickel alloy materials under low-force conditions, while a single-arm tensile testing machine was used for thin film tensile tests. The experimental data obtained were precise, with excellent stability and repeatability.

-

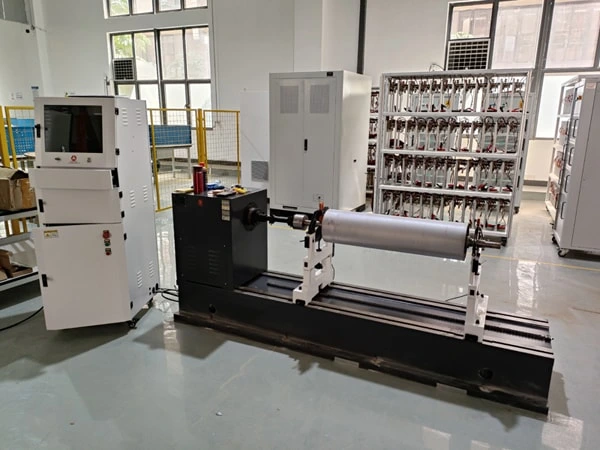

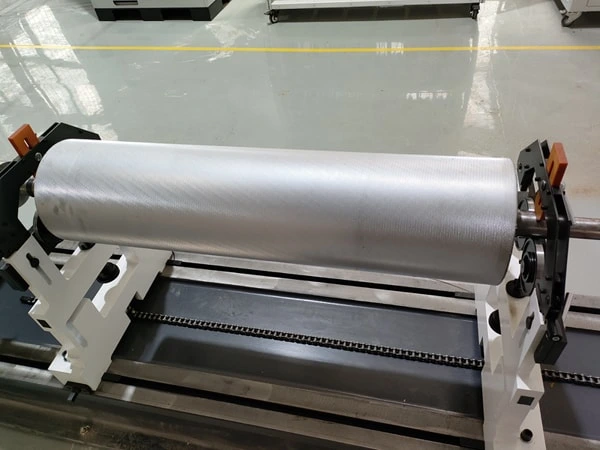

In June 2023, a customer in the plastic powder industry from Haining, Zhejiang, purchased the YLD-100 vertical dynamic balancing machine. The tested component was a plastic powder machine impeller, which operates at high speeds and requires high precision in dynamic balancing. Our balancing machine has shown excellent results in meeting the customer’s accuracy requirements.

-

In September 2023, a university conducted wear resistance tests on pin-disc type materials at 1000°C using the MMUD-5B high-temperature end-face friction and wear tester. The equipment heats up quickly, and its mechanical components demonstrate excellent high-temperature durability. After the test, the clients noted that test data were stable and highly accurate.

-

In October 2023, a water pump impeller manufacturer in Shenyang used the YLD-50 vertical dynamic balancing machine to perform dynamic balance testing and correction on water pump impellers, achieving excellent balancing results.

-

In January 2024, a university laboratory conducted wear resistance tests on metal materials under high-temperature helium protection using a high-temperature pin-disc friction and wear tester. The friction coefficient curve from 1 to 300 N was stable, and the test results satisfied the clients.

-

On March 14, 2024, a customer in the metallurgical industry purchased the YYW-160 horizontal hard bearing universal balancing machine. The tested workpiece was an alloy grinding wheel. The initial imbalance was significant, and the workpiece classification fell between disc-type and shaft-type, making balancing particularly challenging. After technical adjustments, satisfactory test results were achieved.

-

In March 2024, the Energy and Power Laboratory of a university used a rolling fatigue tester to conduct a misalignment load life simulation test on internal combustion engine valve tappets. The test achieved excellent results and received high praise from the customer.

-

In August 2024, a customer in Nanning specializing in testing instruments and equipment purchased the YYW-160 horizontal hard bearing universal balancing machine. The tested workpiece was a dynamometer drum, a precision component of testing equipment that requires high standards of dynamic balancing.

-

In November 2024, a company used a fully automatic four-ball friction tester to conduct long-duration wear tests on mold release oil samples at high temperatures, achieving highly satisfactory testing results.

-

On March 28, 2025, a university primarily used multi-function friction wear testing machine to conduct friction and wear tests on developed materials under various conditions (high and low temperatures, vacuum, salt spray, and current load) and different friction modes, including rotational, reciprocating, and ring-on-block. The modular design allows easy switching between test types, resulting in excellent experimental outcomes.

-

In April 2025, YYW-500-042508 horizontal hard bearing universal balancing machine was used for testing the snow blower drum.

-

On May 19, 2025, the heavy-duty pin-on-disc tester was used at a college in Northeast China to evaluate the wear resistance of the material coating on the rotating components of the arresting gear.

-

On 19 May, 2025, YLD-10 vertical dynamic balancing machine was used by a motorcycle parts manufacturing factory in Pingyin to test the pulley accessories of motorcycles.

Contact Us

Become Our Partners

Grow your business while helping us connect testing machines to markets worldwide. Join us as a local sales representative and be part of our success.