-

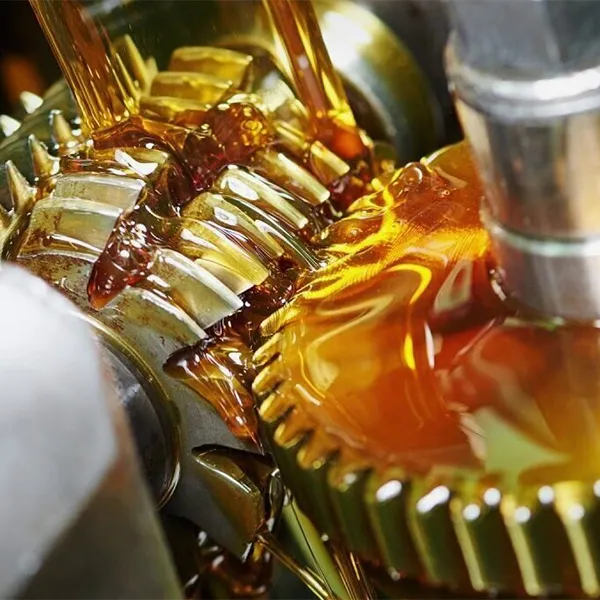

- Friction & Wear Testing Machine for Lubricants Testing Lubricants play a key role in protecting mechanical components, especially under extreme conditions such as high temperature, high speed, pressure, and humidity. Click For More Info

-

- Friction & Wear Testing Machine for Powder Metallurgy Testing Assessing the friction performance of powder metallurgy materials requires precise evaluation methods, one of which is measuring the sample's weight loss to determine wear resistance. Click For More Info

-

- Friction & Wear Testing Machine for Tungsten Carbide Testing Tungsten carbide, known for its high hardness and superior wear resistance, requires precise friction testing to evaluate its performance in real-world applications. Click For More Info

-

- Friction & Wear Testing Machine for Composite Materials Testing Friction testing of composite materials is mainly concerned with their friction coefficients and wear rates. Click For More Info

-

- Friction & Wear Testing Machine for Abrasive Materials Testing Testing the friction and wear resistance of abrasive materials focuses on evaluating their performance under different conditions. Click For More Info

-

- Friction & Wear Testing Machine for Chemical Materials Testing Chemical materials are integral to countless industrial applications, where their durability and performance can significantly impact product quality and longevity. Click For More Info

Explore More Materials Testing Applications

-

- Mechanical Testing Our testing machines perform tensile, compression, and fatigue tests, ensuring reliable data for both metallic and non-metallic materials in various industries. Click For More Info

-

- Dynamic Balancing We offer tailored dynamic balancing solutions based on the type of rotating parts, while considering factors such as weight, diameter, thickness, and the dimensions of the connecting components. Click For More Info