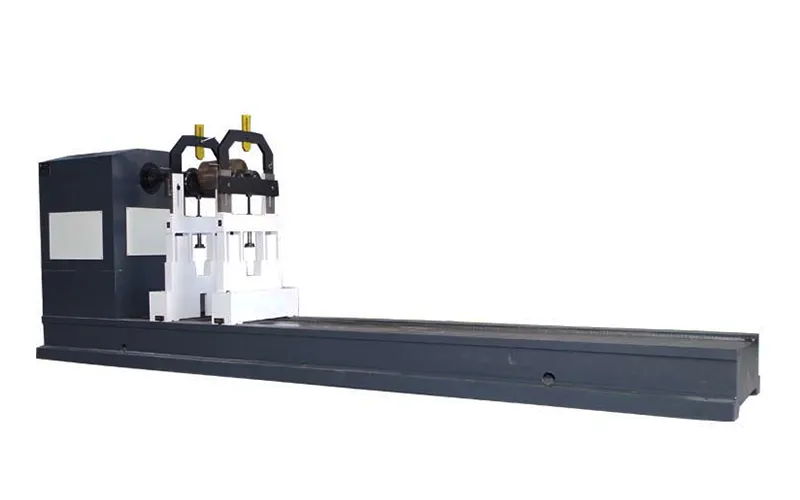

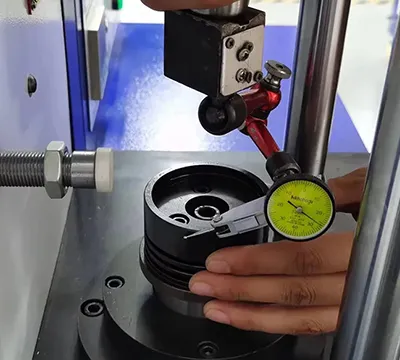

Precision balancing is necessary when dealing with large-diameter components such as fan impellers and blowers, ensuring smooth performance and extended operational life. This horizontal hard-bearing balancing system, tailored specifically for the fan and blower industry, employs roller support with a universal joint drive and variable frequency motor for speed control. An industrial control computer processes real-time data, providing immediate feedback on imbalance values, phase angles, and rotational speed. Suitable for single-plane, dual-plane, and multi-plane balancing tasks, the dynamic balancing machine supports various calibration needs, including standard rotors and custom workpieces. Its flexible design, coupled with advanced software features like coupling compensation, enables precise and versatile measurement, perfect for demanding industrial applications.

Technical Specifications

| Model | Weight of workpiece (kg) | Diameter of workpiece (mm) | Distance between two supports (mm) | Shaft diameter range (mm) | Balancing speed (r/min) | Min. achievable residual unbalance (gmm/kg) | Unbalance reduction ratio (%) | Motor power (kW) | Speed control method |

| YFW-300A | 10-300 | Ø1650 | 1700 | Ø10-180 | Ø300-1500 stepless speed control | ≤0.05 | ≥90 | 5.5 | Variable frequency motor + inverter |

| YFW-1000A | 20-1000 | Ø1800 | 1600 | Ø20-240 | Ø300-1500 stepless speed control | ≤0.05 | ≥90 | 7.5 | Variable frequency motor + inverter |

| YFW-1600A | 30-1600 | Ø2000 | 1600 | Ø20-240 | Ø300-1500 stepless speed control | ≤0.05 | ≥90 | 11 | Variable frequency motor + inverter |