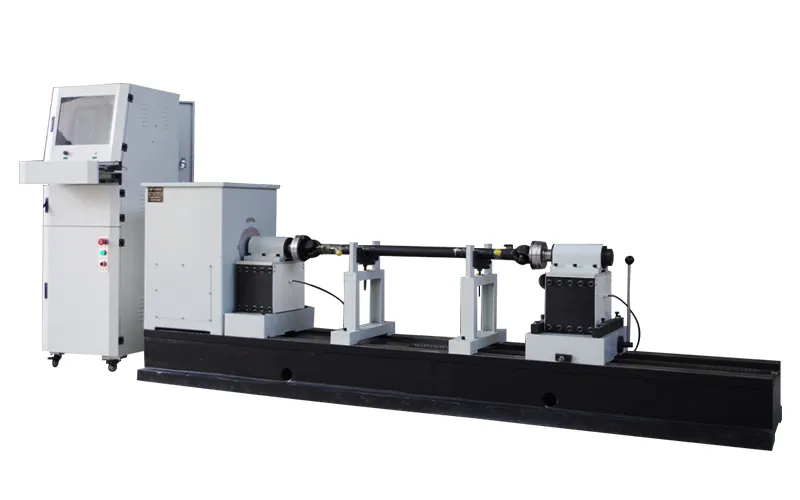

For industries such as shipbuilding and steel manufacturing achieving optimal balance in heavy-duty drive shafts is an important task. This horizontal balancing machine, built for the precise balancing of large-scale drive shafts, adapts easily to different connection types through interchangeable fixtures. Whether used in hard-bearing or soft-bearing configurations, the system accommodates a range of applications. For more demanding projects, customized models can handle drive shafts up to 3 tons. The drive shaft balancer length, along with its fixtures, can also be tailored to meet specific balancing requirements, ensuring reliability across various sectors.

Technical Specifications

| Model | YDW-2000A |

| Max. shaft weight (kg) | 2000 |

| Drive shaft alignment method | Single section double-sided alignment |

| Supporting structure | Rigid bearing |

| Max. workpiece length | 3500mm |

| Bed length | 5300mm |

| Balancing speed | 800-1000r/min |

| Min. achievable residual unbalance | ≤20gmm/kg |

| Unbalance reduction ratio | ≥85% |

| Motor power | 11kW |

Standards

- ISO 11342:1998

Mechanical Vibration — Methods and Criteria for the Mechanical Balancing of Flexible Rotors

-

ASTM D999

Standard Test Methods for Vibration Testing of Shipping Containers

-

ASTM E1012-2014

Standard Practice for Verification of Performance of Horizontal Shaft Rotating Balancing Machines

-

GB/T 9239.1-2006

Mechanical Vibration - Balance Quality Requirements for Rotors in a Constant (Rigid) State - Part 1: Specification and Verification of Balance Tolerances

-

GB/T 11348-2008

Mechanical vibration - Methods and Criteria for the Mechanical Balancing of Flexible Rotors